Choose from a variety of 3D printing technologies

We at IMPACT LABS offer a variety of printing technologies to provide a solution for your needs.

Each technology allows the production of parts of a different size.

Plastic, various technologies:

SLS

ProX500

Prints Nylon 12 parts and quality of final product. Short preparation process. Complex geometric prints.

HP MJF

JetFusion 4200 Print Nylon 12 parts of the quality of a final product with emphasis on small details.

HP MJF

HP 580

Color printer FULL COLOR Manufacturing speed, accuracy, durability and strength, designed for use by development teams in various industries, for manufacturing in small and medium series of parts and products, for product designers, designers and craftsmen.

SLA

Form2

Manufacturing prototypes with multiple details that require smooth terrain. Printing medical models. Fast production. Smooth finish.

PolyJet

Objet30

Precision and a range of high-end rapid prototyping on a desktop 3D printer. Extremely high print resolution. Smooth and shiny surface.

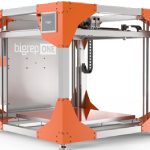

Thermoplastic materials:

Metal 3D Printing:

Direct Metal Printing

PROX DMP 100

3D SYSTEMS

Additive manufacturing of industrial parts required for corrosion resistance or required for high temperature durability.

Direct Metal Printing

PROX DMP 300

3D SYSTEMS

3D printed metal parts manufacturing system, high performance and high quality.

ADAM

METAL X

MARKFORGED

ADAM is an innovative technology that combines metal injection molding with 3D printing.