Prox 300 - DMLS

DMLS is direct metal printing, the parts are built layer by layer. using a method by wich the most complex parts can be manufactured.

Metal powder particles are melted together using a high-precision laser. The laser is aimed at the powder particles in order to selectively build thin horizontal layers. Connecting each new layer to the previous layer, brings a quality alternative to the traditional production processes. The parts are not built by removing material in different stages, but by adding material. One of the advantages derived from this method: fast construction times and the ability to produce very complex assemblies as a single part.

Prox 300 printer

- Optimize features and extremely thin wall thickness.

- Surface finish quality up to 200-5 Ra μ M requiring less Post processing.

- Very dense and non-porous parts.

- accuracy of +/- 50 µm (+/- 0.002 inch) in small parts,

+/- 0.2% on large parts. - Repeatability of about 20 μm

- Creating 20 degree angles without supports.

- Less support and improved quality of space means less Post processing and less use of materials – hence, time and cost savings.

Specifications

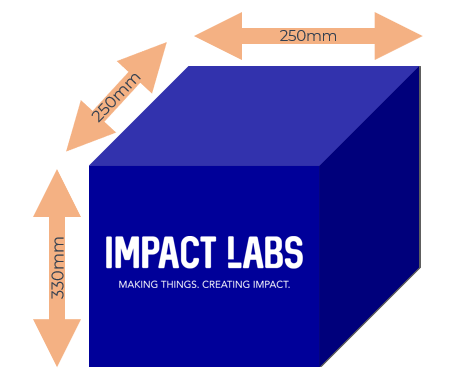

Maximum tray size:

Maximum size of structure: 250X250X330mm.

Minimum production time:

5

2

DAYS

Layer thickness:

Minimum 5 microns

Accuracy:

±0.002MM

Laser power

50W

X-Y resolution

±20μm

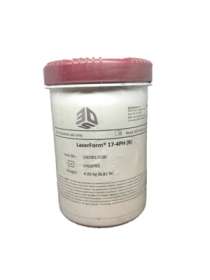

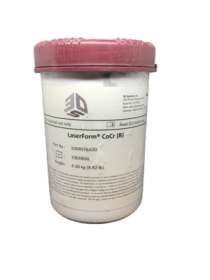

Optional materials:

Stainless Steel 17-4 PH, AlSi12 Aluminum Alloy, CoCr Chrome Cobalt

How to apply Direct Metal Laser Sintering - DMLS

Ready to begin?

Why wait? Submit your parts for production now and let’s start printing!