ADAM - Markforged Metal X

ADAM

Atomic Diffusion Additive Manufacturing

ADAM is an innovative technology that combines metal injection with 3D printing. This unique technology enables the creation of unique and complex geometric structures. The principle of operation of the printer is based on the printing of raw material consisting of a thermoplastic matrix used as a unifying material for the metal powder. This principle allows for new capabilities such as printing partial infill parts (Infill).

These parts enable the creation of an engineering advantage by printing hard, strong, lightweight and economical parts.

Metal X Printer

Metal printing based on fourth generation 3D printing technology.

Metal X is a new type of 3D printer for metal printing. Printing parts with complex geometry in a short time at a significantly low cost in the production of tools and metal parts that are lightweight and have high mechanical properties and strength, production of metal parts with excellent print quality and surface quality.

Specifications

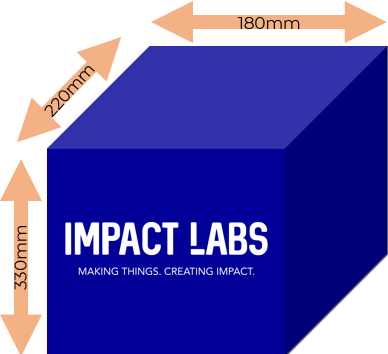

Maximum tray size:

Maximum construction size: 180X220X330MM

Minimum production time (for maximum tray size printing):

3 Business days

3

DAYS

Minimum layer height

50 micron

Possible final weight for part:

10 Kg

Resolution:

50 to 200 micron

Materials in use

Material: Iconel 625

Printer: METAL-X

Particularly suitable for

- Nickel chrome based

- Suitable for functional prototypes and final products

- High temperature resistance

Material: H13 Tool Steel

Printer: METAL-X

Particularly suitable for

- Very hard

- Durable over time

- Resistant to high temperatures

Material: D2 tool steel

Printer: METAL-X

Particularly suitable for

- Very hard

-

Resistant to scratches and bumps

Material: Copper

Printer: METAL-X

Particularly suitable for

- Heat conductor

- Electrical conductor

- spacer

Material: A2 tool steel

Printer: METAL-X

Particularly suitable for

- Very hard

-

High compressive strength

Material: 17-4 ph stainless steel

Printer: METAL-X

Particularly suitable for

- Very hard

- Resistant to high temperatures

- Corrosion resistant

- spacer

How can ADAM be implemented?

From our blog

Ready to begin?

Why wait? Submit your parts for production now and let’s start printing!