Stereolithography - SLA

SLA is a technology based on the use of a photopolymer-type liquid that becomes solid as a result of exposure to light. The liquid is hardened layer by layer by exposing the areas intended for hardening to radiation originating from a laser. The resulting model is accurate and has a smooth surface.

3D Printer : Form 2

Using the Form2 printer, it is possible to produce prototypes with multiple details that require a smooth surface from a variety of materials with unique properties.

Specifications

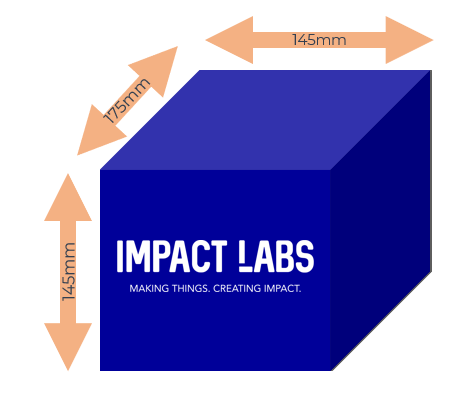

Maximum tray size:

Maximum build size: 145X145X175MM

Minimum production time:

1 business days

DAYS

1

Minimum wall thickness with supports

0.4mm

Minimum wall thickness without support

0.6mm

Minimum column diameter

0.5mm

Minimum hole size

0.5mm

Minimum engraving

0.4mm

Layer thickness:

25-100 micron, depending on the material

Accuracy:

±0.3MM

Material:

Photopolymer resin of various types

Materials in stock

How to apply Stereolithography - SLA

Ready to begin?

Why wait? Submit your parts for production now and let’s start printing!