Selective Laser Sintering - SLS

SLS is a technology based on the use of polymer powder dispersed in uniform and thin layers above each other. In each layer, with a laser beam, the powder passes through a process of heating the pollen to a temperature that is about 80% of the melting temperature of the material, so that the powder particles are connected to each other and form a rigid body embedded in a powder that has not been hardened.

The unused powder supports parts during printing and prevents the need for designated support structures. This feature makes the SLS printers the best for complex geometric prints, thin walls, etc.

Parts manufactured with SLS technology have mechanical properties, including strength and durability, similar to the properties of parts created by plastic injection.

This technology is suitable for rapid production of prototypes and parts made of high-resolution nylon as well as systems made up of moving parts. The models are ready for immediate use in the various industries.

ProX 500 Printer

3D Systems’ printer, combines production speed, accuracy, durability and strength.

Specifications

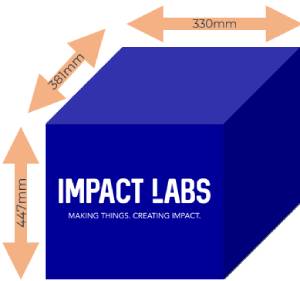

Maximum tray size:

Maximum build size: 381X330X447 MM

Minumum production time:

3 Business days

DAYS

Layer thickness:

80 Micron

Accuracy:

±0.3MM and 2% deviation in large parts

Material:

PA12

Minimum prominent details

0.4mm

Minimum wall thickness with supports

0.6mm

Minimum wall thickness without supports

0.7mm

Minimum drain holes

3

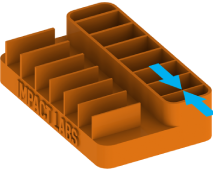

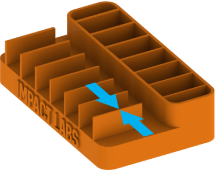

How to apply Selective Laser Sintering - SLS

Ready to begin ?

Why wait? Submit your parts for production now and let’s start printing!